Fences are more than boundary markers; they serve as the first line of defence against various environmental factors and wield significant influence on the aesthetic appeal of your property. But let's face it, maintaining a fence can be challenging, especially in areas with harsh climates. Constant exposure to rain, sun, and wind can leave your once beautiful fence looking faded, chipped, and worse for wear. This is where powder coating comes into play, a finish that brings both aesthetic enhancements and longevity to your fences.

In this comprehensive guide, we dive deep into all things powder coating. Starting from its process—covering the main components and steps involved—to its benefits versus traditional paint finishes, we've got it all covered. We'll also explore its ideal uses, durability, maintenance tips, cost comparisons, and the process of choosing a reliable powder coating company.

Powder coating is a process that applies a decorative and protective finish to metal, aluminum, and other materials. It involves applying a polymer powder coating to an item using an electrostatic spray, then baking it to melt and fuse the powder into a durable, uniform coating.

The powder coating material itself is made up of three main components:

Polymer resin - This makes up the bulk of the powder and provides the protective finish and durability. Common resins used include polyester, polyurethane, epoxy, and hybrid blends.

Pigment - Pigments give the powder its color and opacity. The pigment is mixed into the resin.

Additives - Small amounts of additives are also blended into the powder to enhance specific properties like flow, durability, gloss, etc. Common additives include degassing agents, texturing agents, flow modifiers, and UV inhibitors.

The powder coating is electrostatically applied using a spray gun, which imparts an electrostatic charge as it sprays the powder onto the grounded target object. The charged powder particles adhere evenly across all surfaces. Then the object goes into an oven where the powder melts and fuses into a smooth, durable coating as it cross-links and cures.

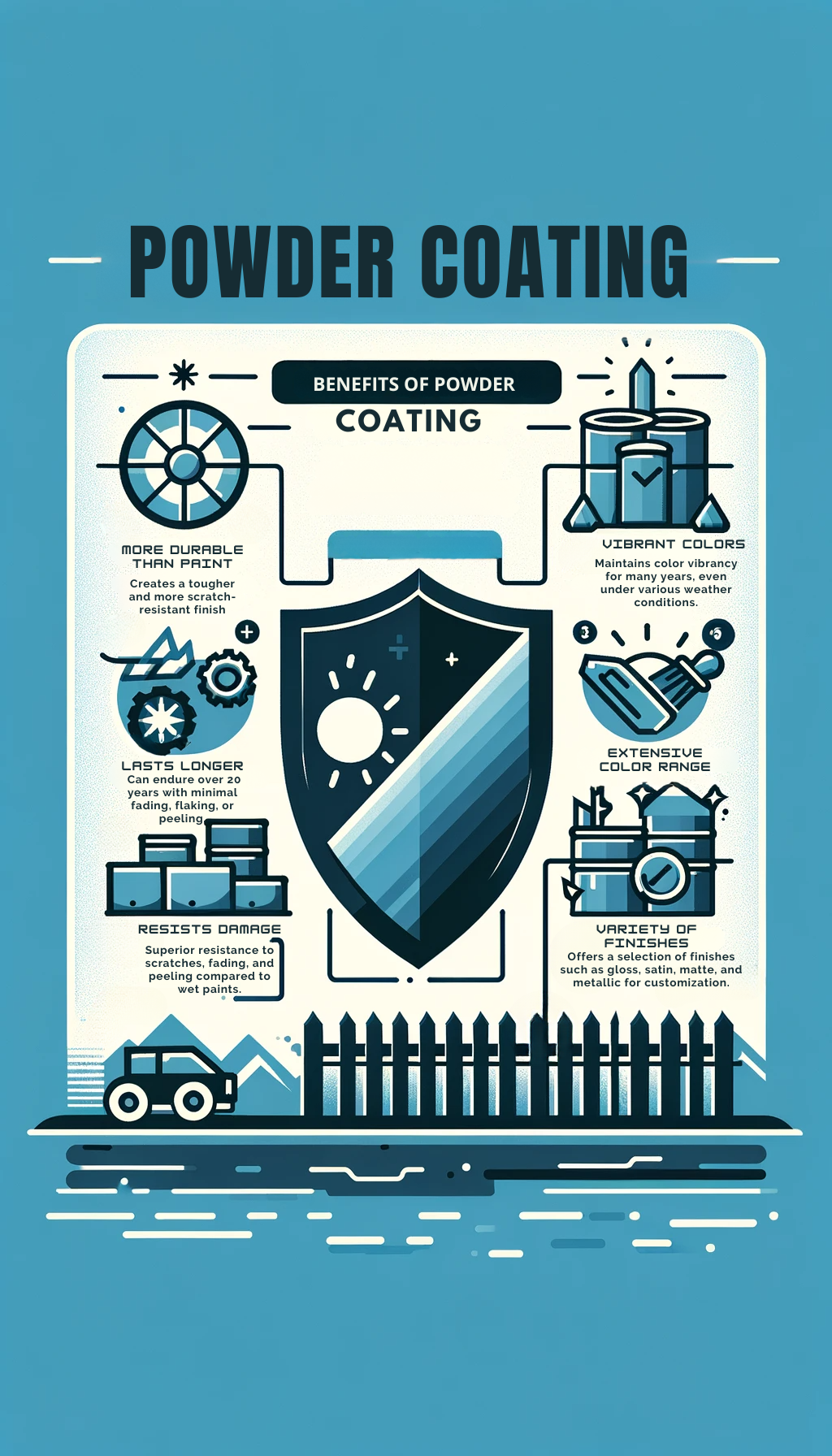

Powder coating offers several advantages over traditional painted finishes for fences and other outdoor structures. Some of the key benefits include:

More durable than paint: Powder coated finishes are tougher and more scratch resistant than standard paints. The powder adheres tightly to the fence and creates a thicker, more durable coating.

Lasts longer: Properly applied powder coating can last for over 20 years on outdoor fences with minimal fading, flaking or peeling. It stands up very well to sun, rain, snow and temperature swings.

Resists scratches, fading, peeling: The tough, baked-on finish resists damage better than wet paints. It won't chip, peel or scratch off as easily as standard paint. The color remains vibrant for many years.

Wide range of colors and finishes: Powder coating can be formulated in virtually any color imaginable. It also allows for different finishes like gloss, satin, matte or metallic. This allows for a high degree of customization.

Powder coating is commonly used on outdoor fences in residential, commercial, and industrial settings. The process provides excellent protection against the elements, making it ideal for fences that will be exposed to sun, rain, snow, and other outdoor conditions year-round.

Some of the most popular uses for powder coated fences include:

Residential fences - Powder coated aluminum, steel, or wrought iron fences are commonly installed around yards, gardens, pools, and other residential outdoor areas. The coating prevents rusting and fading, maintaining an attractive fence for many years.

Commercial fencing - Businesses often use powder coated chain link, aluminum, or steel fencing as secure and durable perimeter fencing. The coating provides long-lasting protection in high traffic areas.

Industrial fences - Factories, warehouses, and other industrial sites rely on powder coated galvanized steel or aluminum fencing to securely enclose large areas while withstanding constant exposure to the elements.

Gates and railings - Matching gates and railings can also be powder coated, providing a cohesive look along with the fence. The coating prevents corrosion and peeling for gates and railings that see frequent use.

Powder coating provides superior durability compared to painting or other coating methods. It's an ideal solution for any outdoor fence made of aluminum, galvanized steel, wrought iron, or other metals that require long-term protection from the elements. The coating allows fences to maintain their original appearance and function for many years.

Powder coating is a multi-step process that results in a durable, high-quality painted finish. Here are the main steps involved:

Surface Preparation

The surface must be thoroughly cleaned before powder coating. This removes dirt, oil, rust, and other contaminants that can cause adhesion problems. Common methods of surface preparation include:

Sandblasting - Uses compressed air to blast abrasives onto the metal surface. This removes rust and creates a rough profile for the powder to adhere to.

Shot blasting - Similar to sandblasting but uses metal shots instead of sand. Also removes rust and creates surface profile.

Chemical cleaning - Involves use of detergents, solvents or other chemicals to clean and etch the surface. Removes oils and contaminants.

Mechanical abrading - Uses abrasive pads, wire brushes or scrapers to manually remove dirt, rust and old coatings.

Powder Application

Once the surface is prepared, the powder coating material is electrostatically applied using a powder gun. The powder particles are given an electrostatic charge as they exit the gun nozzle. This causes them to be attracted to and adhere to the grounded metal surface.

The item being coated is grounded, so the powder sticks and builds up on the surface. Any excess powder is collected to be reused. The powder coats all exposed surfaces evenly with a typical thickness of 2 to 3 mils.

Curing in Oven

After powder application, the item enters a curing oven. It is heated to around 400°F, causing the powder coating particles to melt, flow together, chemically react, and cure into a smooth, seamless finish.

Curing takes around 10-20 minutes depending on the powder used. The oven also hardens the coating fully. The result is a fuse bonded finish up to 10 times thicker than paint.

Additional Protective Clear Coat

A clear top coat can be applied for extra protection and durability. This creates a barrier against UV rays, chemicals, impact, and weathering. It provides a smoother finish and easier cleaning as well. The clear coat is powder coated on and cured just like the base color coat.

The multi-step powder coating process results in a tough, durable finish ideal for high-demand applications like fences, railings, outdoor furniture, and more. The lasting protection resists chipping, fading, and corrosion year after year.

Powder coating is known for its extreme durability and longevity. On average, a powder coated fence can last 15-20 years without chipping, peeling or losing its luster.

Powder coating creates a thick, tightly adhered layer on top of the fence material. This makes it highly resistant to scratches, chips, cracks and other damage from everyday wear and tear. Even if the fence gets scratched, the powder coat will remain fully adhered.

The coating is also formulated to withstand exposure to harsh outdoor elements. The powder polymers cure and bond tenaciously to fence materials, enabling them to stand up well to sun, rain, snow and fluctuating temperatures. Powder coated fences maintain their vibrant colors and protective abilities through years of seasons and weather changes.

With proper maintenance like washing, powder coated fences will exceed expectations for durability. The coating becomes an integral, tough part of the fence, adding many years of longevity over other finishing options. For those wanting a low maintenance, super durable fence that keeps its just-installed look for well over a decade, powder coating is an optimal choice.

Powder coated fences require very little maintenance compared to other fence materials. Here are some tips to keep your powder coated fence looking its best:

Wash occasionally with soap and water using a soft cloth or sponge. Avoid abrasive cleaners or scrub brushes that could scratch the surface.

Touch up any scratches, chips or damaged areas promptly. You can purchase touch up paint or powder coating repair kits for minor fixes. Addressing flaws quickly will prevent further deterioration.

While powder coating is fade resistant, it can still fade slightly over time from sun exposure. Fading is gradual and a small amount is normal. If you notice extensive fading or chalking, you may want to have the fence recoated.

Avoid spraying weed killer or pesticides on the fence, as harsh chemicals can damage the coating.

Inspect your fence each spring and touch up as needed. With proper care, a powder coated aluminum or steel fence can last 20 years or longer before needing to be recoated.

While making a decision between powder coating and traditional painting for your fence, it’s crucial to consider not just the upfront costs but also the long-term implications. Yes, powder coating can seem more expensive initially when compared to painting. But, when you look past the upfront costs, you'll recognize that this investment could, indeed, save you money over time.

The resilience of powder coating means it can last for over a decade without losing its vibrancy or requiring significant maintenance. On the other hand, a standard painted finish may require a new coat every few years, adding to your maintenance costs.

By choosing powder coating, you avoid repeated repainting costs and experience the benefits of a finish that remains fresh-looking for longer. So despite the seemingly higher upfront cost, powder coating can be a cost-effective solution in the long run. Besides, its robustness ensures lasting protection for your fence, which can often be priceless.

When selecting a powder coating company for your fence, there are a few key factors to consider:

Experience with fences - Make sure to choose a company that specializes in powder coating fences and outdoor materials. They should have extensive expertise in preparing, coating, and curing fence components. An experienced fence coating company will understand how to get a durable finish that withstands the elements.

Proper equipment - The company should have a large curing oven to accommodate fence sections and the right powder coating guns and booths. The equipment should be well-maintained. Ask about their process to ensure it meets industry standards.

Reviews and examples - Reputable powder coating companies will have a portfolio of their fence work and great online reviews. Be sure to take a look at examples of finished fences they’ve coated to ensure quality. Speaking with past clients can also give you a sense of their service.

Warranty on work - Choose a company that stands behind their coating services by offering a warranty of at least 5 years on their fence finishes. This ensures they are confident in the durability of their powder coating application.

Always vet a few powder coating companies to compare factors like experience, equipment, and warranties. Investing in a quality powder coating application is the best way to get a long-lasting, low-maintenance finish on your fence.

Powder coating allows for a wide range of color choices and finishes that can dramatically transform the look of a metal fence. While powder coating was historically limited to basic colors like black, white, and brown, advancements in the technology now enable hundreds of options.

Some of the most popular powder coating colors for fences include:

Blacks - Provides a modern, sleek look. Popular choices include flat black or metallic black.

Whites - Creates a clean, neutral aesthetic. Options like gloss white or matte white are common.

Grays - Offers a stylish, urban vibe. Often combined with black accents. Popular shades include gunmetal gray and silver gray.

Bronzes - Gives a natural, earthy feel. Variations include copper bronze, bronze metallic, oil rubbed bronze.

Blues - Provides a cool, calming effect. Navy blue is a top choice for fences.

Greens - Adds a lush, natural element. Often seen in sage, olive, or forest green on fences.

In addition to standard colors, powder coating can create eye-catching special effects such as wrinkles, veins, metallic, matte and more. These options allow for even greater customization and individuality. Before deciding on a color, it's best to get samples from your powder coating company to view how the finishes will look on your specific fence material and in different lighting conditions. With hundreds of possibilities, you're sure to find the ideal colors to transform your fence into a unique focal point.

Powder coating offers many benefits over traditional paint for outdoor fences. As summarized in this article, powder coating is more durable, lasts longer, and resists chipping, scratching, fading, and peeling better than standard paint.

The powder coating process uses electrostatic attraction to apply the powder evenly onto the fence, then cures it into a smooth, tough finish in a heating oven. This results in a fence that stands up extremely well to sun, rain, wind, and other outdoor elements over the years.

Unlike paint which can chip or peel off over time, exposing the bare metal underneath to rust and corrosion, powder coated fences maintain their like-new appearance and protective properties much longer. The thick, evenly-coated powder cured onto the fence prevents moisture from penetrating the metal.

With minimal maintenance required like occasional cleaning, a powder coated fence will continue looking beautiful while protecting your property for over 20 years, even in harsh climates. It's an ideal choice for any home or business wanting a long-lasting, durable, low-maintenance fence that resists the elements.

Overall, powder coating is the premier protective finish for outdoor fences, providing superior durability, longevity, and aesthetics compared to standard paint options. It's a worthwhile investment for fences built to endure.

Powder coating can be applied to many materials, but it works especially well on metals, including steel, aluminum, iron, and wrought iron. These metals are commonly used in fences, making powder coating an ideal finish for protecting metal fences. It can also be used on surfaces like wood, MDF, plastics, and medium density fiberboard.

A powder coated fence can last 15-20 years or more with proper maintenance. The coating won't chip, crack, or peel like paint. It stands up very well to weather and resists fading. With occasional cleaning and touch ups as needed, powder coating keeps fences looking fresh for well over a decade.

The main differences are that powder coating creates a thicker, more durable finish that bonds to the fence surface, while paint sits on top and can chip or peel. Powder coating resists scratches, fading, and corrosion far better. It also offers greater customization of colors and finishes compared to standard fence paint options.

Yes, occasional maintenance will maximize the longevity of your powder coated fence. Wash it once or twice a year using mild soap and water with a soft cloth or sponge. Avoid abrasive cleaners. Also, inspect for scratches or chips annually and use touch-up paint as needed. With minor upkeep, your fence will stay protected and look great.

Absolutely! Powder coating offers many color, finish, and texture options to completely change the look of metal fences. You can choose flat colors, metallics, wrinkled textures, glossy or matte finishes, wood grain effects, and more. It allows you to match your fence to your home's color scheme or create an eye-catching accent.

Powder coating is extremely durable, outperforming standard paint by nearly 10 times in flexibility, impact, hardness, and weather/corrosion resistance tests. Once cured, it forms a seamless, protective finish up to 10 times thicker than paint that bonds to the fence surface rather than sit on top. This makes it far more scratch, chip, and peel resistant.